Project Components

Kaizen and Lean end-to-end transformation for Farm Superstores across 90 branches and central operations in Dammam and Jeddah. Scope covered current-state assessment, visual management with daily Kaizen boards, KPI design, branch profitability analysis, warehouse standards using Collaborative Planning, Forecasting & Replenishment (CPFR), standard work, 5S and ABC, backhaul optimization, and training on value stream mapping and statistical problem solving.

A. The Challenge

Disparate practices across 90 branches, inconsistent replenishment and sales methods, warehouse waste, and limited visual management and KPIs hindered performance, logistics efficiency, and data-driven decisions across Dammam and Jeddah operations.

B. Our Solution

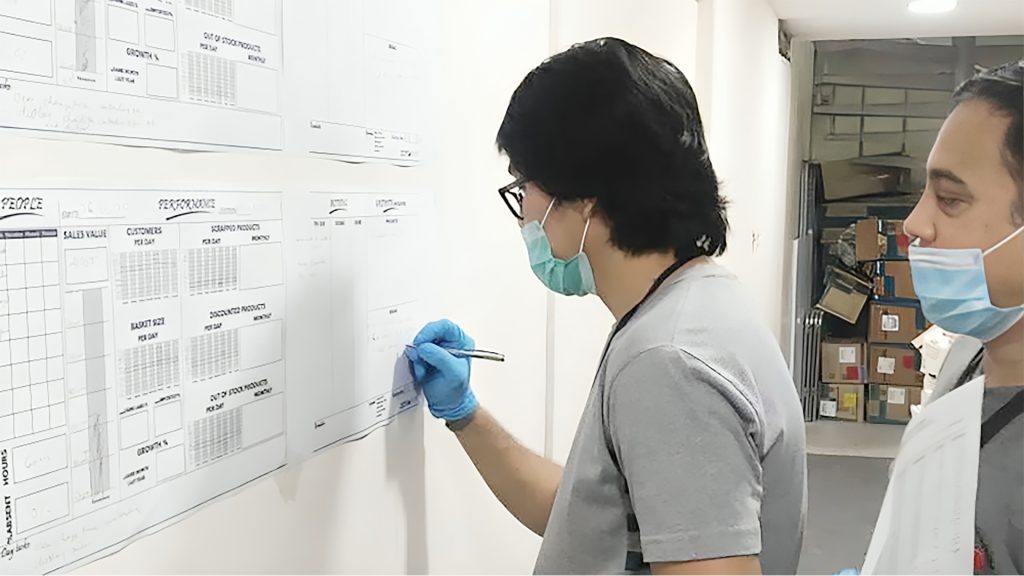

Delivered current-state study; KPI design with daily Kaizen boards; Collaborative Planning, Forecasting & Replenishment (CPFR), mizusumashi, and standard work; applied 5S and ABC; optimized backhaul; trained teams in value stream mapping and problem solving.

C. Key Achievements

Implemented visual boards and KPIs across 90 branches; set CPFR and mizusumashi replenishment; standardized sales work; evaluated 5S and ran ABC at the central factory; optimized backhaul to cut costs; strengthened capabilities through targeted training.

Project Particulars

Client:

Saudi Marketing Company (Farm Superstores)

Start Date:

2020

End Date:

2021

Service Area:

Quality and Institutional Excellence

Client Sector:

Industry

Duration:

Six months

Client URL:

Status:

Completed